Rerurn to Romy the Cat's Site

In the Forum: Melquiades Amplifier

In the Thread: Superior electric binding posts

Post Subject: Torque & clampingPosted by jessie.dazzle on: 9/26/2009

fiogf49gjkf0d

Romy wrote :

"...With my kind of cables and the spades that they use the force of my fingers is not enough to tight the binding posts..."

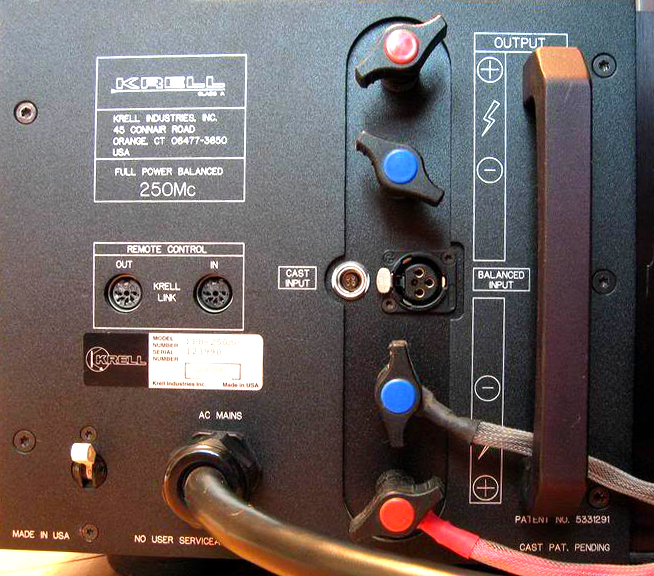

It would be nice if Superior would issue a design that used the same metal parts as their existing posts, but had nice big plastic wing nuts like some of the old Krell amps used to have. This would of course require that the plastic wing nut be attached by some other means than is currently the practice; they are simply pressed over shallow splines in the metal part that turns. This is why using a wrench on the Superior's current posts is not a good idea.

I too use "The Paul Technique", which turns the fundamental problem with most binding posts (rotational forces are not isolated from clamping forces) to our "advantage". The designs that use washers under the nut do not (with very few exceptions) entirely isolate rotational forces from clamping forces.

The best temporary connection is stranded bare wire that has been properly clamped... The bare part of the wire should be gold plated to prevent oxidation. I wish such an option were a standard offering among cable manufacturers.

Then, to properly clamp that wire, we would need a good split-bolt connector.

Below is such a connector... Yes its sort of crude, but the same concept could be refined for audio (don't forget the wing nut!). This design isolates rotational forces from clamping forces, while properly confining the strands of wire.

jd*Rerurn to Romy the Cat's Site